Dongguan, Guangdong Jan 15, 2026 (Issuewire.com) - The integrity and presentation of cardboard packaging, especially corrugated boxes, directly influence brand perception and product safety during logistics. In the high-volume, competitive world of converting, the final texture and smoothness of the paper surface are not accidental; they are the result of precision finishing processes. Calendering, which uses pressure and heat to compress and smooth paper or board, is crucial for improving density, gloss, and printability, particularly before subsequent processes like laminating or varnishing. As demand for high-resolution graphics on corrugated materials grows, the need for top-tier calendering technology becomes indispensable. Sourcing equipment that combines mechanical robustness with precise control is a key strategic decision for manufacturers aiming for superior product quality and operational efficiency. As a Best Quality Paper Calendering Machine Supplier in China, Sunkia Machinery has dedicated its operations to high-end post-press solutions, providing advanced systems like the Automatic High-Speed Calendering Machine, which is engineered to deliver enhanced surface characteristics and increased paper rigidity crucial for modern packaging standards.

The Evolving Landscape of Corrugated Packaging and Post-Press Finishing

The corrugated packaging industry is experiencing a dynamic transformation, driven by e-commerce growth, customization demands, and the necessity for superior surface aesthetics. These trends have significantly elevated the role of specialized finishing equipment.

Finishing Trends and Market Demand

Modern corrugated packaging is moving beyond brown shipping boxes to become sophisticated retail displays and brand communication tools. This necessitates machinery capable of achieving higher visual quality on thicker substrates. The calendering process, which improves the paper's density and uniformity, directly impacts the success of subsequent finishing steps. For instance, a properly calendered surface ensures smoother application and better adherence of lamination films or varnish coatings, minimizing defects and improving the final product's tactile quality and durability. The industry trend is moving toward Automatic High-Speed Calendering Machines that can handle various board weights and achieve a consistent finish at fast production rates, thereby mitigating bottlenecks in high-volume production lines.

Sunkia Machinery, with its 15-year history specializing in high-end post-press machines, recognizes this need for precision finishing tools. As a high-tech company that also develops intelligent paper coating machines and owns patented technology in multi-function laminating machines, the company possesses the integrated knowledge base necessary to design calendering equipment that seamlessly fits into a complex finishing workflow.

Sino Corrugated: A Window into Corrugated Finishing Trends

International trade exhibitions serve as critical platforms for manufacturers to validate their technical advancements, understand regional market needs, and demonstrate operational readiness to a global audience. The company has a consistent history of participating in major international trade shows, showcasing its commitment to engaging with the global market and continually benchmarking its technology against international standards. This commitment is evidenced by its presence at key events like Sino Corrugated, which focuses specifically on the corrugated and packaging industry, offering critical insights into the finishing equipment required to meet global production demands.

More On Interpretnews ::

- Transformer Home: China’s Best Foil Winding Machine Factory with CE Certified Standards

- MD Diagnostic Specialists Offers Comprehensive Care for Accident Injuries in Maitland

- Chuangxiang Highlights Innovation at the 138th Canton Fair as a China Top Automatic Napkin Machine Manufacturer

- As Inflation Squeezes US Businesses, SetMyCompany.com Offers Strategic Access to India’s Growth Engine

- PerfectARC Launches on Indiegogo to Revolutionize Basketball Shooting with Precision Tech

The Relevance of Sino Corrugated

Sino Corrugated, being a key event in the Asian packaging supply chain, brings together the entire corrugated manufacturing ecosystem, from raw paper production to final converting and finishing. The exhibition acts as a major platform where companies demonstrate the capabilities of their latest machinery for processing heavy-duty materials. For a specialized paper calendering machine supplier like Sunkia Machinery, participation allows direct engagement with manufacturers facing challenges in optimizing board surface quality for high-fidelity printing and precise folding. The observed trends at such events consistently highlight the need for:

Automation: Minimizing manual intervention for roll changes and process adjustments.

Precision and Uniformity: Achieving consistent smoothness and rigidity across the full width of wide boards.

Intregation: Ensuring the calendering step operates efficiently at speeds compatible with upstream printing and downstream converting lines.

The focus seen at Sino Corrugated is often on robust machinery engineered to handle the high-stress environment of corrugated board production while maintaining the necessary finesse for surface refinement.

Sunkia's Technical Edge and Quality Assurance in Calendering

Sunkia Machinery's position as a provider of high-quality calendering solutions is anchored in its foundational technical capabilities and strict quality control processes.

Engineering for Surface Excellence

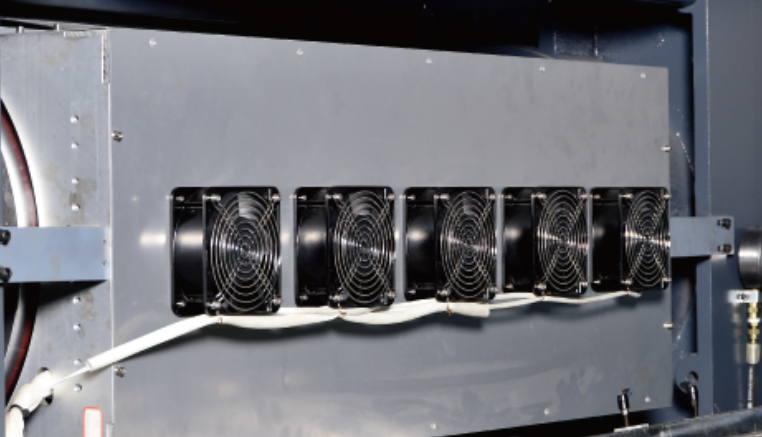

The paper calendering machine supplier emphasizes engineering that directly tackles the challenges of high-speed, high-quality board finishing. The Automatic High-Speed Calendering Machine is designed to significantly enhance the surface gloss and feel of paper packaging. This is achieved through the use of precisely machined rolls and controlled pressure application, which are essential for increasing the density of the paper fibers without causing structural damage to the board. Enhanced density leads to better resistance against crushing and smoother surfaces for printing inks, enabling more vibrant and sharp graphics on corrugated materials.

The equipment is backed by a strong technical research & development team and a first-rate production team located in Dalingshan Town, Dongguan City, Guangdong Province. This regional manufacturing hub provides the logistical and engineering support required for producing large, precision post-press equipment. Furthermore, the companys status as an ISO certified company and the presence of the CE certificate on their machines confirm a commitment to verifiable quality management and safety standards, providing procurement professionals with confidence in the long-term reliability of the equipment.

Core Benefits and Application Impact

The key advantages delivered by these calendering solutions translate directly into enhanced product quality for the end-user:

Improved Print Quality: By smoothing the paper surface, the machine reduces ink absorption variability, making colors appear more uniform and graphics sharpera non-negotiable requirement for high-end retail packaging.

Increased Rigidity: The compression process enhances the structural integrity and density of the paperboard, improving its stack strength and resistance to damage during transport and warehousing.

Efficiency in Finishing Workflow: Calendering equipment that operates at high speeds and provides reliable consistency ensures that subsequent processes, such as varnishing or film lamination, can be carried out without costly downtime or material waste due to poorly prepared surfaces.

A customer specializing in high-end consumer electronics packaging, for example, relies heavily on this level of surface preparation. The glossy, uniform surface achieved by advanced calendering is essential before applying premium varnish or lamination, ensuring the final box meets the aestheticstandards expected for luxury goods. The machinery becomes a strategic asset in transforming basic board into a high-value consumer package.

Strategic Investment in Finishing Technology

The selection of a paper calendering machine supplier is a strategic decision that dictates the quality and efficiency of a packaging manufacturers entire finishing line. Sunkia Machinerys dedication to providing high-end post-press equipment, supported by patented technology and stringent quality credentials, addresses the contemporary industry demand for both superior surface aesthetics and operational throughput. Insights gleaned from industry events like Sino Corrugated confirm that the future lies in automated, precision calendering solutions that enhance material properties for better printability and structural integrity. Investing in this caliber of equipment allows manufacturers to confidently meet the escalating quality requirements of the global corrugated market.

For further information on automatic high-speed calendering machines and post-press innovation, visit: https://www.sunkiamachinery.com.

Media Contact

Guangdong Sunkia Machinery Technology Co., Ltd.

+86 0769 82782808

745# Shida Road, Dalingshan Town, Donguan Cicty, Guangdong Province, China

Source :Guangdong Sunkia Machinery Technology Co., Ltd.

This article was originally published by IssueWire. Read the original article here.

6 day's ago