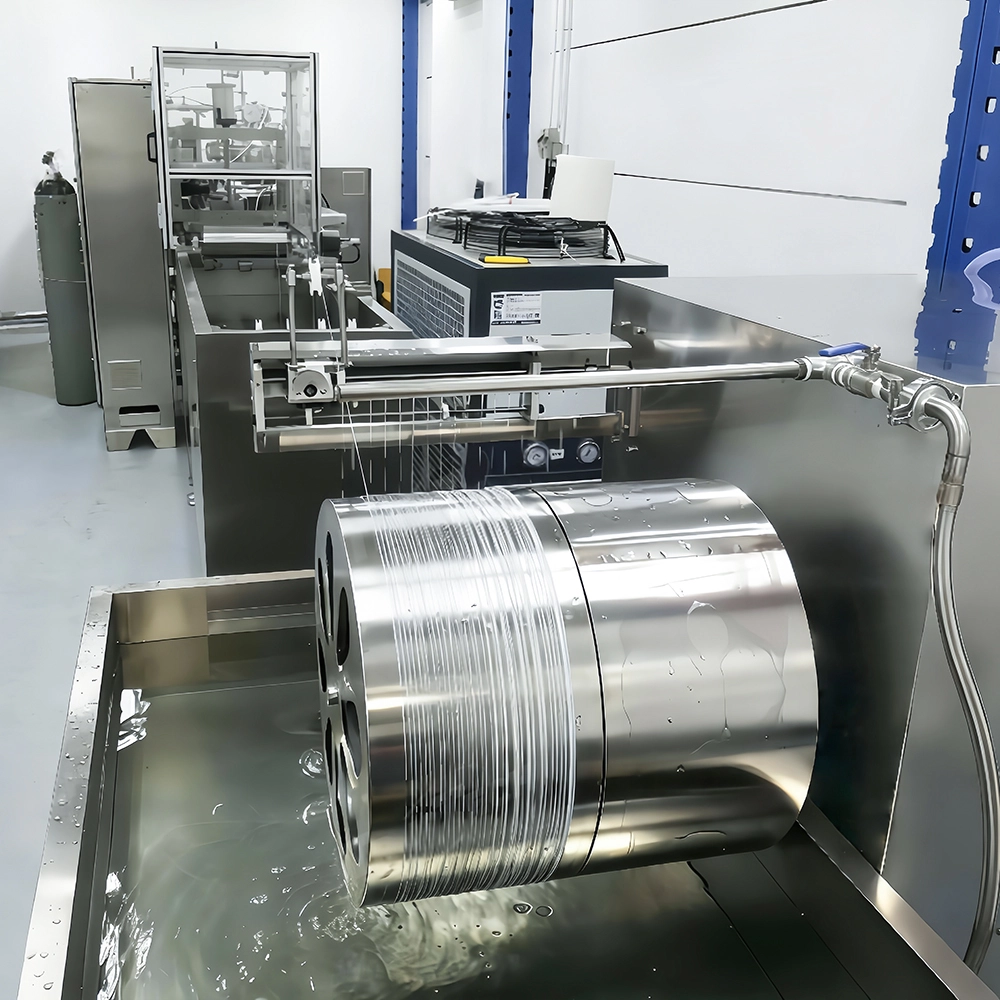

Jiading, Shanghai Jan 4, 2026 (Issuewire.com) - As the international environmental technology sector strives to meet higher precision and durability standards, Shanghai Trustech Technology Development Co. Ltd. successfully demonstrated its technical know-how at the inaugural "Environmental Star Product PK" competition. At an industry event designed to measure the operational efficiency and reliability of green manufacturing technologies, a Leading Stable And Reliable Hollow Fiber Membrane Spinning Equipment was recently featured as an example of modern fabrication standards for membrane fabrication. This system is an advanced manufacturing platform designed to create hollow fiber membranes through controlled extrusion and phase inversion processes. By integrating high-precision spinnerets with advanced automation, this equipment ensures uniform fiber wall thickness and pore distribution that are essential for maintaining efficient wastewater treatment and dialysis treatment applications. Trustech's technology was recognized during the evaluation process for its mechanical stability and digitized control interfaces, placing them among the top eight finalists out of an extremely competitive field of industrial solutions.

1. Global Membrane Technology Trends and Industry Evolution

The international filtration landscape is witnessing an industry transition away from labor-intensive assembly toward automated, high-capacity fabrication environments. As regulatory bodies adopt stringent water reclamation and pollution control standards, resilient hollow fiber media demand has skyrocketed. Modern production systems favor eliminating human error for consistent polymer extrusion across millions of meters of fiber; hence increasing the need for equipment capable of maintaining thermal and mechanical balance during 24-hour industrial cycles.

Key Industry Trajectories and Technological Demands:

The Trend toward Automated Production: The global market no longer settles for standard filtration - instead requiring high-flux, anti-fouling membranes capable of withstanding chemical exposure - which drives demand for spinning platforms to eliminate manual interference for an uninterrupted production lifecycle with stable structural rejection rates throughout.

Technological Requirements for Resilient Fiber Structures: With the rising popularity of carbon capture and chemical processing requiring high viscosity materials like PVDF, resilient fiber structures must possess exceptional bursting strength membranes to meet this increasing need. Modern equipment must now include sensitive tension controls and synchronized winding units in order to avoid microfractures during phase inversion processes involving advanced polymers like PVDF.

Sustainability and Resource-Efficient Production: Industry leaders have recently shown greater interest in "lean" manufacturing lines that reduce chemical waste while optimizing dope consumption. Intelligent spinning equipment featuring Industry 4.0 features like remote monitoring and automated fault detection has now become the norm among Tier-1 producers.

Analysis of Environmental Star Product PK Competition

More On Interpretnews ::

- Stopping to Move Forward: Tanya Stevenson’s “The Wild Pause” Redefines Success in a Culture Obsessed with Doing

- Exclusive: Low-Volume Custom PCBA Motherboard Supply Solutions from FR4PCB.TECH

- China Insulated Cooler Bags Factory Unveils Ultra-Durable Leak-Proof Designs for 2026

- Georgi Grover Recognized by BestAgents.us as a 2026 Top Agent

- LED China Highlights Envision as a Top Transparent LED Screen Supplier with Full TUV - RoHS Compliance

The inaugural "Environmental Star Product PK" serves as a specialized forum for screening new generations of environmental hardware. Unlike general exhibitions where products are simply displayed, this competition uses an exhaustive benchmarking format to identify equipment with optimal balances between energy efficiency, technical reliability and environmental impact. Trustech's spinning system was selected as industrial solutions meeting "Star Product" criteria; judges assessed its ability to maintain high-precision output under stress simulation conditions.

Core Objectives of the Star Product PK Event:

Validating Engineering Excellence and Reliability: This competition features live technical audits and performance assessments that recognize engineering maturity required to compete against an elite field of competitors. Reaching the Top 8 validates Trustech's research into mechanical stability of extrusion lines.

Fostering Zero-Defect Manufacturing Philosophies: This event underscores how stable hardware contributes to environmental footprint reduction. Furthermore, precision micro-manufacturing has become an integral component of global green infrastructure initiatives and circular economy practices.

Catalyzing Innovation in Environmental Equipment: The competition prioritizes original engineering innovation over imitation, fostering meaningful breakthroughs while promoting cross-sector knowledge exchange and highlighting membrane separation as a critical, cross-functional technology for safeguarding air, water, and soil resources. In parallel, the upgraded SpinMaestro 2.0 spinning system significantly enhances precision and operational stability through advanced subsystemsincluding the SteadyiCore Ultra 2.0 heating system, TitanMix Pro 4.0 mixing system, PrimeGlider Pro 3.0 automatic pay-off, SmartCoil Elite 3.0 automatic winding, and StoutDrive 2.0 motor drive configuration. Collectively, these innovations improve system reliability, reduce commissioning and production downtime, and increase overall spinning efficiency by 11.4% compared with previous designs.

3. Core Technical Competencies and Application Scenarios

Trustech's technical leadership can be measured by its ability to maintain extreme mechanical tolerances across its entire spinning line. By optimizing fluid dynamics within its spinneret assembly and doping system, Trustech equipment reaches concentricity of up to 0.003mm that eliminates fiber eccentricity that often results in early membrane failure. Furthermore, its automated control interface enables real-time adjustments of extrusion parameters for consistent fiber diameters regardless of viscosity fluctuations in polymer dope doping systems.

Primary Application Scenarios for Trustech Systems' Products:

Municipal and Industrial Wastewater Treatment: Trustech systems play a significant role in producing high-strength membranes used by Membrane Bio-Reactor (MBR) systems to effectively recycle effluent recycling while safeguarding water resources, enabling safe reuse of treated water for irrigation or high intensity industrial cooling applications.

High-Precision Biomedical Membrane Filtration: This technology supports the manufacturing of membranes used for hemodialysis and artificial lungs (ECMO). Mechanical consistency is of critical importance in these lifesaving applications and ensures uniform blood flow and diffusion rates across its porous surface.

Gas Separation and Energy Efficiency Initiatives: Specialized fiber geometries manufactured by Trustech machines support nitrogen generation and carbon capture, facilitate the recovery of hydrogen gas in chemical processing operations, as well as assist the global transition toward cleaner energy by decreasing atmospheric emissions from industrial facilities.

Trustech operates across 39 countries and services over 630 customers with its AAA-credit rating to build trust among them. They collaborate with institutions like Changchun Industry University to bridge material research with industrial scaling; actively taking part in Membrane Industry Association of China to set new manufacturing benchmarks.

Conclusion: Raising the Bar for Modern Membrane Production

Trustech's spinning equipment's selection at the Environmental Star Product PK competition speaks to their commitment to mechanical integrity and operational transparency. By integrating precision engineering and innovative machine design, Trustech mees global challenges of consistency and scalability in membrane production. Trustech continues to lead the evolution of separation science by making advanced membrane technology available worldwide through reliable engineering solutions that ensure its benefits can be realized for global health and water preservation. Trustech offers proven, dependable engineering solutions designed to enable this transformation.

Trustech's achievement as one of the Top 8 Finalists represents not just an award to itself but an endorsement for industries relying on high-performance filtration every day. Through continuous innovation and dedication to engineering excellence, Trustech continues to lead the separation science revolution, creating cleaner and healthier futures through precision.

For more information regarding technical specifications, product portfolios, and corporate developments, please visit the official website: https://www.xtrustech.com/

Media Contact

Shanghai Trustech Technology Development Co., Ltd.

Source :Shanghai Trustech Technology Development Co., Ltd.

This article was originally published by IssueWire. Read the original article here.